Product Engineering

Product engineering refers to the process of developing and designing an item or device. This includes any assembly so that it may be mass produced through a manufacturing process.

We have many customers who come to us with an idea for a new product, and request help taking it from concept to a production-ready status. Some customers have only a sketch of their idea on paper.

“I very rarely think in words at all. A thought comes, and I may try to express in words afterwards” – Einstein

Our engineer can bring your idea of a product to life. He will walk you through the process of creating the manufacturer-ready drawings a factory will need to put your product into production for you to sell. Together he will inform you of costs, producibility, performance, quality and more.

Consultation

The first step would have an initial phone call with our engineer to describe the concept for your product, including the materials you envision it being made from, rough dimensions, how it should function, and any other details. The more information you can provide, the better. This could include rough sketches, sample parts or components, prototypes, or other drawings you might have had made. Our engineer will be happy to help in getting your creative ideas ready for a manufacturer to produce.

Upon request, we are happy to sign a non-disclosure agreement (optional) with you where we agree to keep your product design and concept confidential. We have a standard NDA we can provide, or we can work with your NDA.

Our engineer has years of experience working with products made from multiple materials, including metal, plastic, and textiles. He’s done work for Dell Computer and other large tech companies.

Quote for Product Engineering & Design

Next we will provide you with a quote for the estimated hours necessary to create an initial rendering. First generation drawings, and other processes that might be needed, such as the inspection of any prototypes and final drawing revisions are included in this quote.

Because we offer engineering and production sourcing services under one roof, we’re able to provide competitive rates that are often 50% below some engineering firms.

Our engineer is concerned with your design in how it looks, how it works, how it is controlled, how people or nature may interact with it and always helping, guiding, and consulting in helping you create an amazing product for production.

Designing & Engineering

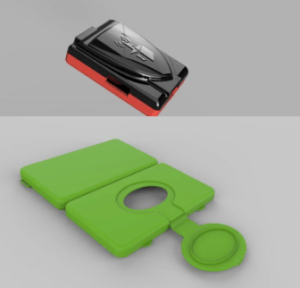

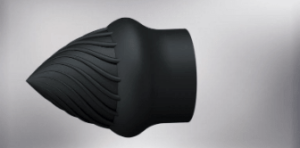

Once you’ve made the decision to work with us, our engineer may produce some initial computer-generated renderings to give you a feel for what your product would look like.

Once you’ve made the decision to work with us, our engineer may produce some initial computer-generated renderings to give you a feel for what your product would look like.

The next step will be to create first generation drawings of all parts. These drawings will include all dimensions, tolerances, material, and finish requirements. A 3d model may also be created, in stp file format.

Product Testing & Prototyping

Once you’ve approved the first generation drawings, prototypes should be made for every new product so you can test that the function and fit are what you have in mind. Prototypes also give you products that you can show to your prospective customers for market research purposes.

We will also provide you with a quote from one of our manufacturers that specialize in making prototypes after the first generation drawings are complete.

Quality Testing of the Prototype

Once the prototypes has been made you may use it for marketing purposes and to perform your own tests. Make sure you gather feedback from the people testing your product and let them contribute ideas to your product.

Once the prototypes has been made you may use it for marketing purposes and to perform your own tests. Make sure you gather feedback from the people testing your product and let them contribute ideas to your product.

Product Revisions & Updates

There are always changes that are made after the first prototype is made. Your customers might make suggestions that would enhance your product’s features, our engineer could come up with ideas to help improve the design for manufacturing purposes, or the prototype might provide you with the spark for new ideas or improvements.

Finalizing Product Drawings for Production

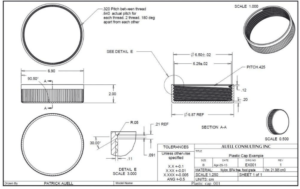

Engineer drawings are usually complex because they include all the engineering of how the product is assembled. Manufacturing drawings are simpler in that they show the detailed specifications such as sizes, weights, welding information, surface information and material type of the parts so that your product may be manufactured. Both are very important.

Once you’ve fine-tuned the design, our engineer will produce final, production ready drawings, and we will be ready to go to China for a production quote.

“The value of achievement lies in the achieving.” – Einstein

The engineering and prototyping process is different for every product. Some projects might require multiple design changes and prototypes, while others, if the products are simple, could be done with several sets of drawings and one prototype. We will work with you to expedite the product development phase as quickly as possible.

Please contact us to discuss getting the engineering process started.